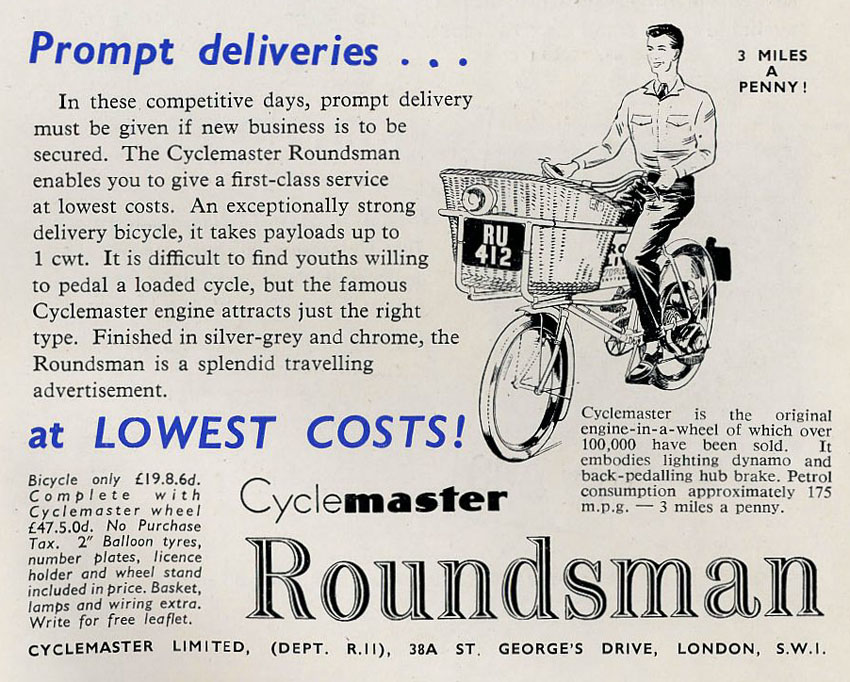

In these competitive days, prompt delivery must be given if new business is to be secured.

The Cyclemaster Roundsman enables you to give a first-class service at lowest costs.

It is difficult to find youths willing to pedal a loaded cycle, but the famous Cyclemaster engine attracts just the right type.

– Advert for the Roundsman from Cyclemaster Ltd, London SW1

William Richard Morris is obviously best known as Lord Nuffield, founder of Morris Motors Ltd. But, like many other British car manufacturers, he started out, before the car’s invention, with a bicycle shop.

Like many small cycle builders around the country, Morris used proprietary parts to supply a local market. This means that his machines had few distinguishing features to identify them as Morris bicycles. So, with a low production rate, only a few of his machines survive.

With little hope of finding an original Morris bicycle, I was therefore delighted to discover this machine.

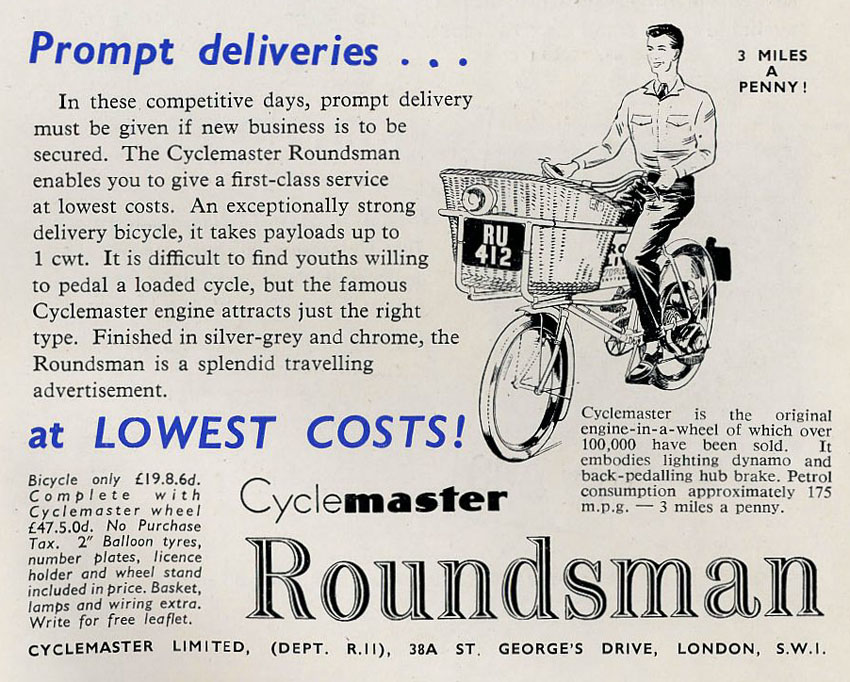

Although not a bicycle built by Morris himself, it is a unique vehicle in its own right, being a motorised Raleigh Low Gravity Carrier owned by the MG factory in the early 1950s to move items around the Parts Department at Abingdon.

1952 Raleigh ‘Low Gravity Model 47’ Carrier

Cyclemaster Roundsman owned by

The MG Riley Parts Dept at Abingdon

(Now sold)

I sold this on ebay in 2013 and it’s now in the USA. This was my ebay blurb:

This Cyclemaster Roundsman was used as a factory runaround by the Morris/MG/Riley parts dept, and was purchased by an enthusiast from that area in 1980 after the factory closed. I bought it in 2008, taking it out of storage recently to be serviced so I could ride it around Brighton. As you can see in the video below, it starts easily and runs well.

Apart from the cars themselves, I’ve never come across a free-standing display item relevant to MG, Riley or Morris cars. So this unique machine is ideal for any exhibition of vintage MG cars, for publicity use in a leading car dealership, or as a museum piece. As the above Cyclemaster Roundsman advert points out:

‘The Roundsman is a splendid travelling advertisement.’

VIDEO OF THE MG PARTS DEPT CYCLEMASTER ROUNDSMAN

To see the video on youtube

http://youtu.be/QpK7NiLUMtk

PLEASE CLICK HERE

WILLIAM MORRIS EARLY HISTORY

William Richard Morris was born in Worcester in 1877, and raised in Cowley, Oxford. He learned to ride a bicycle in 1891, aged fourteen. Harry Edwards reports:

They went along Garsington Road, then a rough road with high hedges and a wide grass verge, and William soon mastered the machine. His burning ambition at the time was to open a cycle shop in the High Street. In later years, William Morris is supposed to have told Mr Smith: ‘I wish I still had that old bike your father taught me to ride on; I’d hoist it above my garage.’ Encouraged by his achievement, William Morris put his savings into a second-hand, cross-frame safety with solid tyres, which he would constantly take to pieces and reassemble. This was the period when cycling had an enormous following as a sport, with clubs all over the country, meeting at weekends. Motorcars were virtually non-existent and bicycling was a respectable mode of travel and sport. Indeed, one could get a full blue at Oxford University for cycling. Morris was soon an accomplished cyclist and began bicycle racing in Oxfordshire.

Cycling pals of William Morris were Reg Smith’s father, mentioned above, and Bill Simmonds. One day the three decided to cycle to Witney. Smith and Simmonds knew that Morris had no money and when they got in sight of the toll bridge at Swinford they speeded up and went ahead. ‘The chap behind will pay’ they shouted to the toll keeper. When Morris could not pay, the toll keeper let the gate go hitting Morris’s back wheel and he and the cycle finished up in a heap on the grass verge.

In 1893, family circumstances changed and William Morris left school and started work at the Oxford Cycle Co, 68 St. Giles, Oxford. After nine months, he left to work for himself, setting up business in a brick building behind his parents’ house at 16 James St, Cowley. His first customer was a Rev Pilcher who, at 6′ 4″, required a custom built machine, duly built by Morris. Harry Edwards continues:

Personal recommendation by the Reverend Pilcher soon brought further orders, and Morris’s mother allowed her son to use the front room of her double fronted house as a showroom. Repaired cycles would stand in the front garden. Cycles made by Morris carried a transfer on the frame in the form of a cycle wheel in gilt, with the words’ The Morris’ underneath. Stock and expenses had to be kept to a minimum, to make his capital go far, and working hours were necessarily long. On occasions Morris would cycle the 50-mile round trip to Birmingham to get components. BSA, Chater Lea, Eadie Manufacturing Co. and Components Ltd. all made parts for cycle makers to use in the assembly of their own machines. Perry & Co. of Birmingham, a supplier of roller chains, allowed Morris a maximum credit of £25.

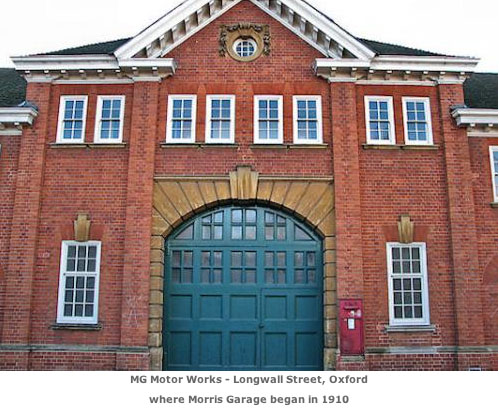

…His good reputation was being reflected in a growing turnover. As well as repairing bicycles and building them to order, he soon expanded, handling other makes including being agent for Rudge Whitworth. In the Oxford commercial directories for 1896 and 1897 can be found the entry; ‘William Richard Morris cycle maker’. As the nineteenth century moved to a close, the business had out- grown the home workshop at James Street, and he began to look around Oxford for suitable alternative rented premises.These he found at 48 High Street, Oxford.

For a short while he still continued to make use of the workshop at his parents’ home, and the 1901 Oxford directory listed ‘W R Morris, practical cycle maker and repairer, 48 High St and James St Oxford, sole maker of the celebrated Morris cycles’. The shop in High Street, which still exists today, has a graceful and distinctive front, comprising four arched window frames. It proved a good choice as a showroom, for a considerable trade was done in repairs to undergraduates’ machines and the premises were almost opposite the Examination Schools.

Morris’ advertising was direct and to the point. Around 1903, he was pointing out that he had had 12 years experience in cycle construction and could build you a cycle,or repair your existing one, no mater how badly it was worn or broken. Re-plating and enamelling from 25/- (£1.25) or handlebars plated for 2/6d (22.5p). His business, he claimed, was the only place in Oxford where plating, enamelling and lining were all executed on the premises. ‘You are not kept waiting by me whilst the parts are sent away to Coventry or elsewhere to have this work done’. Other services offered included the hire of first class ladies or gents cycles by the hour, day week or term; ‘cruets, tea and coffee sets, forks spoons etc. plated for hotel work’. His advertising added ‘ I cannot afford to do bad work or sell bad goods, I want you to come again.’

Meanwhile, although mainly concerned with bicycles, Morris was making his first moves towards establishing himself in the field of motorised cycles. In 1900 he purchased a proprietary single cylinder 11⁄2 horsepower engine, which he fitted into a frame of his own design. He had a display at the 1902 London Motor Exhibition, which was the beginning of a new and successful career. After further years of selling, hiring and repairing cars, he was in a good position to assess the popularity of different models of automobile.

After further years of selling, hiring and repairing cars, he was in a good position to assess the popularity of different models of automobile. Resenting the American domination of the British car market, he had in mind a mass-produced value-for-money motor similar to the Model T Ford. He established Morris Motors in 1912, introducing his first car, the Morris Oxford, the following year.

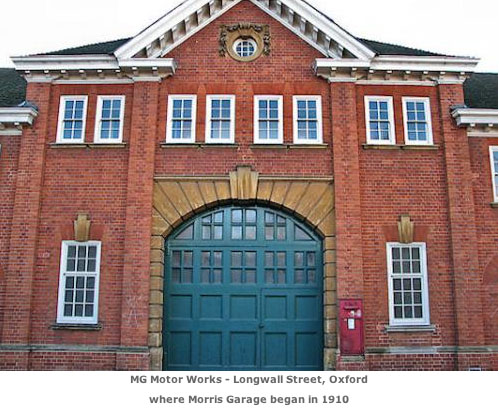

MG ABINGDON FACTORY

In July 1930, the M.G. Car Co Ltd was registered to take over the production of sports cars from The Morris Garages Ltd, in a factory in Abingdon. The Nuffield Organisation and Austin Motor Co. Ltd merged in April 1952 to form the British Motor Corporation (BMC). This brought the Austin, Morris, M.G., Riley, Wolseley and Morris Commercial marques into common ownership.

It’s interesting to consider the environment in which this motorised Raleigh Low Gravity Carrier Bike operated. Geoff Armstrong, an MG enthusiast who worked at BMC, explains that whereas Coventry had over 7000 employees, Abingdon had a workforce of 1200. The Abingdon factory was also located in a rural area, with many workers from the surrounding Oxfordshire countryside. Many of their parents had worked on the land or in local service industries. This provided a much more relaxed working environment than in most car factories:

Abingdon was a more relaxed work environment with the employees taking greater pride in their products and quality. It did not go unnoticed either that Abingdon’s MG car works was seen as … one of the personal interests, or as some would say ‘hobbies’, of Lord Nuffield, of the original Morris Garage.’ Another difference was that there were no motorized paced conveyers on the car assembly line. Instead the cars were assembled on a ‘buggy’ or trolley-like unit. Then, when the workers completed the work at their station, they simply pulled or pushed the car down to the next assembly station by themselves. This gave the work groups a considerable degree of autonomy about who did what and when. As such, the pace was not as intense, relentless nor machine-driven as existed in a traditional automobile assembly operation. This is not to say the workers did not have a quota of cars to be built by the end of the day but how they did it was more up to them than management direction.

Armstrong also mentions that Abingdon had a barbershop at the factory. If a worker needed his hair cut (there were no women on the assembly line) the worker would inform his fellow workers at their assembly station. They would then attempt to work ahead to allow the worker who needed a haircut to jump off of the track to get his hair cut and then rush back in time to not delay production.

So the workers were efficient in their own way and economical production was never given the priority one would expect in mass-produced cars. But part of that phenomenon was because everyone at Abingdon did not see themselves as just making cars …they were making MGs!

THE CYCLEMASTER ROUNDSMAN & RALEIGH LOW GRAVITY CARRIER

Morris pre-car history thanks to Harry Edwards; published in The Boneshaker magazine, No 162, Summer 2003, titled William Morris – Cyclist and Cycle Builder

Geoff Armstrong’s Abingdon insights thanks to Mike Losey: The Closing of Abingdon: End of the MG Era, by Michael R. Losey (Member: 10701) New England MG T Register, Ltd